Laminate housings

Laminate housings

Polyester-glass laminate housings are a reliable solution wherever components resistant to mechanical damage, corrosion and weather conditions are required. Composite materials of this type are characterised by excellent strength combined with low mass content in the structure, making them a particularly attractive choice in many industrial sectors. Polyester-glass laminate combines design flexibility with the ability to produce complex shapes, even in limited quantities.

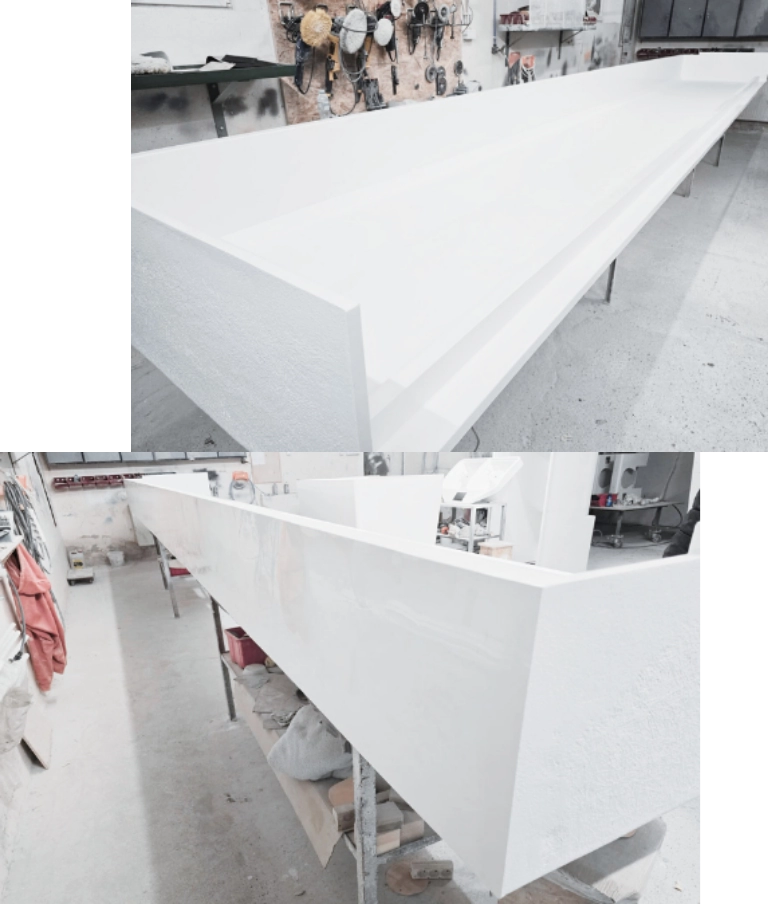

We successfully manufacture both large-size covers and small elements with unusual geometries. Production is carried out in accordance with strict technical and quality standards, using modern laminating technologies. Our solutions perform well in challenging operating conditions, and each project is tailored to individual technical and functional requirements.

Advantages of laminate housings

The greatest advantages offered by laminate enclosures include high chemical resistance, low thermal conductivity, and great freedom in terms of shaping. Composites of this type are corrosion-resistant, do not deform under the influence of moisture, and ensure a long service life even in extreme conditions. Laminates enable the production of covers with an aesthetic appearance and smooth surface, without the need for additional finishing.

Consistent quality and the possibility of using a variety of resins, colourants and reinforcements make it possible to optimally adapt the product to the requirements of a specific application. Compared to their metal counterparts, laminate housings are characterised by significantly lower production costs while maintaining similar strength parameters.

Use of polyester-glass laminate housings

Laminate housings are widely used in many industries. Due to their functionality and high technical parameters, they are often used as covers for industrial equipment and technical installations. The polyester-glass laminate housings we manufacture are used, among other things, as:

- housings for refrigeration units and HVAC systems,

- covers for air conditioners, server rooms and power cabinets,

- security components for antennas, sockets and light fittings,

- components of bakery machinery, industrial robots and sanitary equipment.

Due to the possibility of producing elements with complex shapes, laminates are also suitable for applications where individual adaptation to the technological space or operational requirements is necessary.

Design and manufacture of custom-made laminate housings

As part of our comprehensive customer service, we offer the design and manufacture of custom-made laminate housings, taking into account all technical, ergonomic and aesthetic aspects. The implementation process begins with an analysis of the documentation, consultation on design parameters, and selection of optimal materials. The 3D models created on this basis enable precise shape reproduction and quick corrections before the moulding stage.

Each design can be produced as a single prototype or as part of a production series. For customers seeking advanced technologies, resin infusion can be an alternative to traditional lamination. In this regard, RTM manufacturer offers support in the field of resin injection into closed moulds. This solution is particularly effective in the production of components requiring repeatability and high surface quality. RTM technology enables the production of smooth and durable components with complex geometries.

Composite structure in housings

Each of our laminate housings is made of an advanced composite material whose unique properties result from the close cooperation of two main components: the matrix and the reinforcement. The matrix is a resin system (e.g. polyester) which acts as a binder – it surrounds and protects the reinforcement fibres, transfers loads between them and gives the element chemical and thermal resistance. Reinforcement, most often in the form of fibreglass, forms the structural skeleton, responsible for key mechanical parameters such as tensile strength and rigidity. Only by combining these two components can a material be obtained that is lightweight, extremely durable and resistant to external conditions.

Types of reinforcement and mechanical properties of the housing

Choosing the right type and layout of reinforcement is critical to the final parameters of the casing. Depending on the design requirements, we use various forms of fibreglass. The most common are glass mats, made of randomly arranged, cut fibres. They provide good isotropic properties (the same in all directions) and adapt perfectly to complex mould shapes. For components subjected to high, directional loads, we use glass fabrics with a regular weave, which offer significantly higher strength along the fibre axis. For the most demanding applications, where extreme rigidity with minimal weight is essential, we use carbon or aramid fibre reinforcement.

How do we match the resin to the laminate housing?

The type of resin used determines not only the mechanical properties, but above all the chemical and thermal resistance of the finished product. In our production, we use three main resin systems, selecting them precisely for the working environment of the housing. Polyester resins are standard, offering the best price-quality ratio in most industrial applications. When laminate housings are to be used in contact with aggressive chemicals (acids, alkalis) or at elevated temperatures, we use vinyl ester resins. However, in designs requiring the highest strength, minimal shrinkage and excellent adhesion, we use advanced epoxy resins.

Reinforcing laminate housing structures

For the production of large, flat surfaces that need to be highly rigid while remaining lightweight, we use sandwich structure technology. It involves placing a lightweight core material (e.g. PVC foam, PET or honeycomb structure) between two layers of laminate. This treatment significantly increases the rigidity of the component without significantly increasing its weight. Furthermore, in order to ensure local strength in critical areas, we design and laminate integrated reinforcements in the form of ribs, profiles or sleeves for mounting holes. The result is a uniform, monolithic structure with optimised strength.