Vacuum infusion

Vacuum infusion

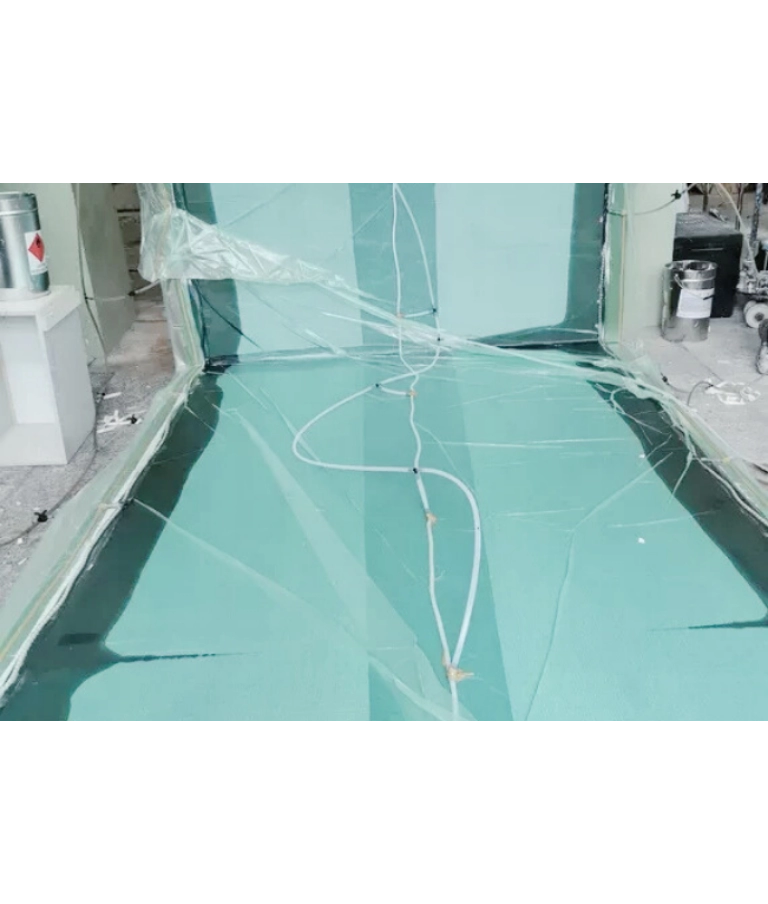

We are a manufacturer of laminates using the infusion method, a technologically advanced process that enables us to achieve high levels of strength and excellent mechanical properties. This method involves laying dry reinforcement in a mould covered with gelcoat. Next, lay the mesh to improve resin flow, and finally the delamination fabric. All of this is sealed in an airtight vacuum bag. After pumping out the air, resin injection is performed. The pressure difference causes the resin to be distributed evenly throughout the mould.

In which industries are laminates produced by infusion used?

Laminates manufactured using the infusion method are widely used in many industries where lightness, strength, precision and durability of the material are key:

- Aerospace industry – composite laminates are used in the manufacture of structural components for aeroplanes, gliders, drones and satellite components. Examples include wing covers, stabilisers, aircraft fairings and interior panels.

- Automotive industry and specialised vehicles – in the automotive industry, infusion is used in the production of body components, covers, spoilers, engine housings and canopies. Laminates are also used in the structure of lightweight special vehicle bodies.

- Construction and infrastructure – infusion-moulded laminates are used in roof structures, façade panels, technical covers and interior design elements.

- Maritime industry – in shipbuilding, infusion-moulded laminates are the basic material used in the production of hulls for sailing yachts, motorboats and deck components.

- Wind energy – laminates are used to manufacture wind turbine blades, which must be lightweight yet durable and resistant to changing weather conditions and long-term loads.

- Rail transport and public infrastructure – infusion composites are used in the structure of railway carriage interiors, door panels, technical covers and bodywork for rail vehicles.

Advantages of laminate production using infusion technology

Infusion technology is widely used in the production of laminates. As a result, it is possible to achieve a high level of strength and accelerate the entire production process of large-size components. On top of that, infusion allows us to:

- lower laminate production costs – thanks to reduced resin consumption, waste reduction and minimisation of production errors, it is possible to significantly reduce unit costs compared to traditional methods;

- maintaining consistent product quality – controlled vacuum conditions eliminate the risk of air pockets and ensure a uniform level of impregnation in each production batch, which translates into consistent technical quality;

- production of laminates with consistent wall thickness – the infusion process enables precise management of the amount of resin in the structure, resulting in uniform elements with a specific thickness, without deformation or local deviations;

- production of laminates with a perfect bond – infusion guarantees complete bonding of composite layers without blisters or discontinuities, resulting in increased mechanical durability and resistance to operating conditions;

- selection of various resins and fabrics – the flexibility of the technology allows for the use of a wide range of raw materials, from epoxy to polyester resins, as well as various fibres (glass, carbon, aramid), tailored to individual project requirements. An important advantage of this method is the reduction of harmful chemical emissions. Manufacturing the product using infusion results in styrene emissions that are ten times lower than with traditional technology.

Materials used in the laminate infusion process

Specialised materials are used in the infusion process, the selection of which depends on the functional and environmental requirements of the finished product. The most commonly used materials are glass and carbon fabrics, roving mats or hybrid structures combining different types of fibres. Each reinforcement must have adequate permeability and be arranged in such a way as to facilitate resin flow.

In terms of chemistry, epoxy and polyester resins are of key importance, as they are adapted to the operating parameters: temperature, curing time and bonding strength. Auxiliary components are also necessary: separation films, distribution grids, sealing tapes and drainage systems. Their synergistic action makes vacuum infusion an extremely precise process, but one that requires complete control over every stage.

Performance of laminates made using the infusion method under various conditions

The efficiency of this technology depends on a number of environmental and technical parameters. High humidity, temperature or contamination can affect the viscosity of the resin or its gel time, but under controlled production conditions, the method maintains exceptional repeatability. This makes it possible to mass-produce components with identical structure and quality.

The process demonstrates high production flexibility – both for large-size moulds and smaller functional elements, such as housings for machines or medical devices. In such cases, the ability to achieve a perfect external surface without the need for additional processing is crucial. The finished laminates are distinguished by their precision, lightness and resistance, making them an attractive choice in many industries.

Costs of producing laminates using the infusion method

The production of laminates using the infusion method involves costs that depend on the scale, complexity of the mould and type of materials used. The unit cost decreases as the volume increases, making the method cost-effective for serial orders. Investment in vacuum systems and precision tooling returns by reducing production time and minimising waste.

In addition, vacuum infusion of laminates reduces resin consumption, which directly translates into raw material savings. Despite higher initial costs compared to open methods, this technology provides significantly better mechanical properties and higher surface quality. It thus responds to the needs of sectors that do not accept compromises.

Vacuum infusion of laminates in the automotive industry

The use of vacuum infusion in the automotive industry is currently one of the most important trends in the production of lightweight and durable components. This technology is widely used in the construction of sports car bodies, technical component housings, internal body structures and aerodynamic covers. It plays a special role where weight must be reduced without compromising structural integrity.

The infusion method allows for accurate reproduction of mould details, which gives freedom in designing components with complex geometry – both visual and structural. This also enables the integration of multiple functions into a single component, reducing the cost of manufacturing and assembling the entire subassembly. Furthermore, vacuum infusion ensures high aesthetic quality of the product, reducing the need for varnishing or additional surface finishing.

The automotive industry is constantly striving for optimisation – reducing weight, increasing durability and improving driving performance. Infusion-moulded laminates meet these requirements, offering solutions that combine durability with lightness, and precision with cost-effectiveness.

High reinforcement-to-resin ratio

One of the fundamental advantages offered by vacuum infusion is the possibility of achieving a very high fibre volume fraction in the laminate, often exceeding 60%. In practice, this means that the composite structure contains the maximum amount of reinforcement responsible for load transfer and the minimum amount of resin acting as a binder. This is because atmospheric pressure (acting through vacuum) first compacts the dry reinforcement package, removing almost all the air from between the fibres, and only then is a precisely measured amount of resin introduced into this space. The result is laminates with significantly higher strength and stiffness at the same weight compared to laminates made using open methods.

What influences successful vacuum infusion?

The correctness of the infusion process depends on the strict control of a number of interrelated parameters. Our technologists analyse and select the optimal variables before each cycle. The viscosity of the resin is crucial; it must be low enough to flow freely through densely arranged reinforcement, which is directly dependent on the ambient temperature and the resin itself. Equally important is the level of vacuum achieved (measured in millibars) and its stability over time. We also develop an individual mould feeding strategy, precisely positioning the injection and vacuum ports to ensure an even and predictable resin flow front, eliminating the risk of premature gelation or dry spots.

Requirements for infusion process tooling

Unlike hand lay-up, moulds designed for infusion must meet significantly higher technical requirements. First and foremost, they must be completely airtight in order to maintain a stable vacuum throughout the entire injection and curing cycle, which often lasts several hours. The surface of the mould must be class ‘A’ quality, as any imperfections will be perfectly reflected on the surface of the finished component. The mould structure must also be sufficiently rigid so that it does not deform under atmospheric pressure (approx. 10 tonnes per square metre). By investing in precision tooling made of composites or metal, we guarantee dimensional repeatability and the highest aesthetic quality of the components we manufacture.

Production of sandwich structures using vacuum infusion

Vacuum infusion is a technology ideally suited to the production of advanced sandwich structures. This process allows for simultaneous resin saturation of both the outer layers of reinforcement (so-called skins) and their bonding with a lightweight core material (e.g. PVC foam, PET or a honeycomb structure). This results in a monolithic, structurally integrated panel with incomparably higher rigidity and bending resistance than a solid laminate of the same weight. This technique is fundamental in the production of large and lightweight components, such as yacht decks, special vehicle body parts and wind turbine blades, for which the stiffness-to-weight ratio is a critical parameter.

How do we avoid defects in laminates produced using the vacuum infusion method?

Our experience allows us to identify and eliminate potential process defects before resin infusion takes place. A key stage of the inspection is the so-called ‘drop test’ – after closing the vacuum bag and pumping out the air, we switch off the pump and monitor any drop in vacuum pressure for a specified period of time. This allows even the smallest leaks in the system to be detected. Additionally, to prevent the so-called corridor effect (when the resin flows faster along the edges of the mould, blocking the path to the centre), we use appropriate flow retarders or accelerators. The care taken over these details means that our laminates have a uniform structure, free from air bubbles, dry spots or other internal defects.