Machine housings

Machine housings

Demanding industrial environments require components that not only protect the mechanics, but also increase the safety and ergonomics of the equipment. Machine housings made of polyester-glass laminate are a solution for manufacturers who expect durability, low weight and the ability to design according to individual needs. Laminate moulding technology allows for the creation of complex shapes that are precisely tailored to machine structures.

Laminates are resistant to chemicals, moisture and UV radiation, which makes them suitable for both indoor and outdoor applications. Additionally, the surface of each housing can be prepared for painting or made of gelcoats with high mechanical resistance. This solution ensures both aesthetics and functionality while maintaining a low weight of the structure.

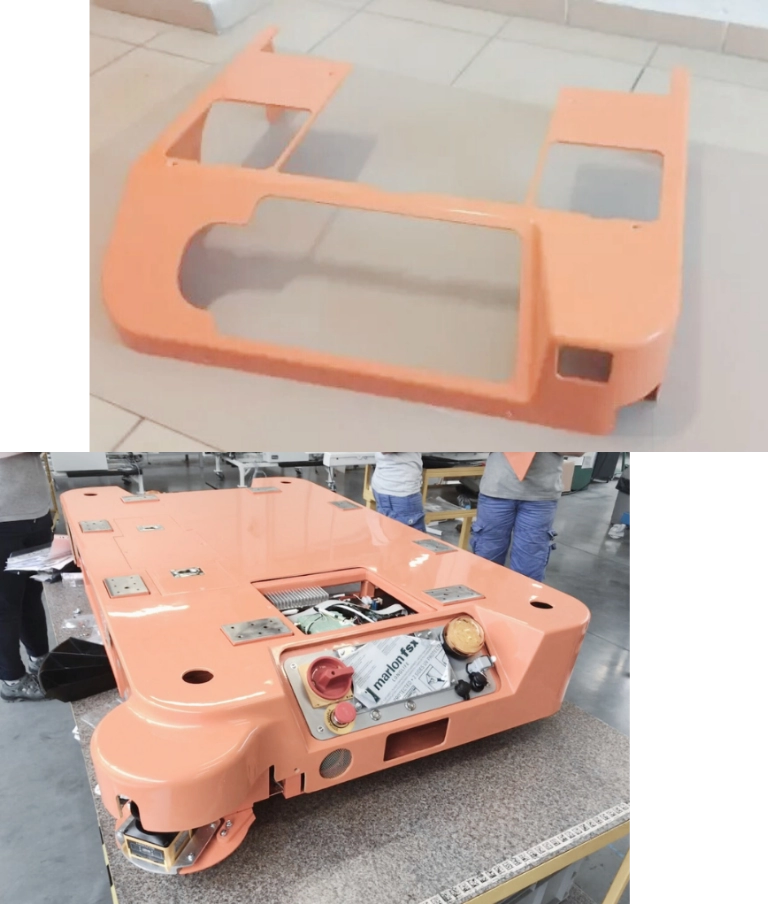

Laminate housings for self-propelled robots

Laminate housings for self-propelled robots must meet high requirements in terms of durability and integration with sensor and camera systems. The use of laminate enables the production of housings with complex geometry, allowing for their full integration with the function and aesthetics of the robot.

Vacuum infusion or RTM techniques are used in production, which guarantee high surface quality and controlled wall thickness. This makes it possible to obtain repeatable components in series production, which is crucial when implementing automation on a larger scale.

Laminate housings for automation

Laminate automation housings provide high electrical insulation, low thermal conductivity, and resistance to vibrations and mechanical damage. When designing them, it is possible to include openings for connectors, cooling systems or component installation.

An additional advantage is the possibility of producing enclosures with different wall thicknesses and surface finishes – from matt to glossy, with optional laser marking or screen printing. As a result, the casing can be not only functional, but also consistent with the manufacturer's visual identity.

Laminate housings for filtering and ventilation devices

Housings for filtering and ventilation devices manufactured from laminate combine tightness, chemical resistance and lightweight construction. The use of this material allows for the production of highly durable components without the need for additional reinforcement structures.

The housings can be equipped with integrated flanges, inspection hatches and fasteners, which facilitates installation and maintenance of the devices. Thanks to their corrosion resistance, laminates are ideal for industrial plants, laboratories and outdoor installations.

Laminate housings for bakery machines

In the food industry, ease of hygiene maintenance and resistance of materials to contact with high temperatures and cleaning agents are of significant importance. Bakery machine housings made of laminate meet these requirements while offering durability and low weight. Their surface can be easily cleaned, and the structure does not absorb moisture or odours.

Another advantage of laminate in this case is its chemical inertness and the possibility of moulding it without visible joints, which eliminates the risk of dirt accumulation. Work safety is also extremely important in the food industry – laminate does not conduct electricity, which reduces the risk of electric shock.

Laminate housings for engines and motorboats

Laminate motor and motorboat housings are components that are resistant to weather conditions, abrasion and temperature fluctuations. Thanks to their high rigidity and low weight, they are ideal for mobile applications.

The possibility of manufacturing the housing in any colour, shape and structure allows it to be matched to the design of the vessel, while ensuring resistance to deformation and mechanical damage. Among customers in this industry, laminates are particularly valued for their durability in marine and inland conditions.

What is the process of designing custom machine housings?

We begin our cooperation with the client with an in-depth technical analysis. Our engineering department works on the basis of supplied 3D CAD models or, if necessary, creates them from scratch based on concepts, 2D drawings or even existing objects. A key stage is optimising the design for the selected moulding technology (Design for Manufacturing), which reduces costs and maximises production efficiency. For machine housings with particularly demanding designs, we offer the option of conducting strength analyses using the finite element method (FEM). This enables verification of the component's behaviour under load and optimisation of its geometry even before costly tooling is produced.

Matching material properties to industry specific features

The standard chemical and mechanical resistance of the laminate is just the beginning. It is possible to modify the composition of the composite to give it specialised properties required by specific industry standards. Depending on your needs, we can manufacture housings for machines with increased flame retardancy (using self-extinguishing resins) or providing electromagnetic shielding (EMI/RFI) by integrating conductive layers into the laminate structure. Such advanced modifications are crucial in sectors where, for example, medical device housings or components for rail transport are manufactured.

Tool technology and the scale of serial production of machine housings

The cost and service life of a production mould are significant factors in the budget of any project. Our consultancy services include selecting the optimal tool technology depending on the anticipated production volume. For prototypes and short series of machine housings, we offer the production of cost-effective composite moulds that allow for quick and inexpensive production start-up. For large-scale projects involving thousands of units, we design and manufacture metal (e.g. aluminium) tooling, which is characterised by significantly higher durability and dimensional stability, guaranteeing full repeatability throughout the entire product life cycle.

Ready-made component for the production line

We supply not only raw shells, but complete, ready-to-assemble components. Among other things, we offer precise painting in any colour from the RAL palette, application of coatings with increased scratch resistance, and application of graphics. However, we also go one step further – as part of the final assembly, we can equip the housings with the necessary additional components. We glue and seal windows or inspection hatches, install threaded metal inserts in the laminate structure, fit hinges, locks, seals and acoustic or thermal insulation materials. This provides our partners with a ready-made module, significantly reducing time and costs on their own assembly line.